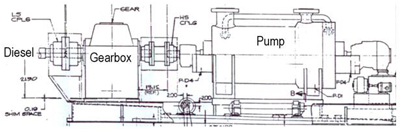

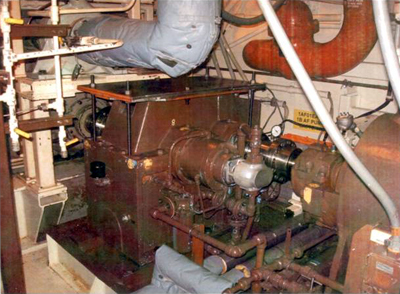

Step-Increase at 1x on Turbine-Driven Feed Water Pump:

A sudden step-increase in vibration levels observed on a turbine-driven feed water pump is a concerning indication of a potential machinery defect for any client. Furthermore, additional testing indicated the levels were continuing to increase, signaling a rapidly degrading process, heightening the risk of component failure. If left unaddressed, the impending failure of this critical component could necessitate a forced de-rate of up to 35% in the nuclear power plant’s generation.

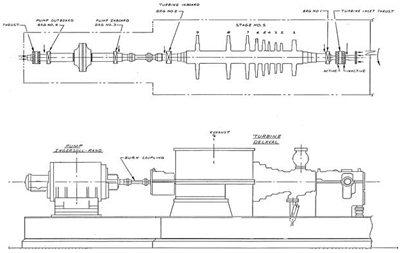

Given the implications for plant performance and safety, prompt action is imperative. Conducting a thorough analysis to identify the root cause of the vibration anomaly is paramount. Possible causes may include mechanical wear, misalignment, imbalance, or resonance issues within the turbine-driven feed water pump assembly.

Once the root cause is determined, appropriate corrective measures should be implemented to mitigate the risk of failure and restore the equipment to optimal operating conditions. These measures may include repairs, realignment, balancing, or even replacement of damaged components.

By addressing the underlying issues proactively, the plant can minimize the likelihood of costly downtime, prevent safety hazards, and uphold operational reliability. Additionally, leveraging advanced monitoring techniques such as vibration analysis can help preemptively detect similar issues in the future, enabling timely intervention and proactive maintenance strategies.

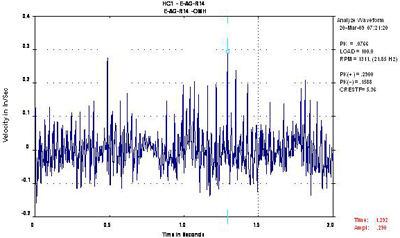

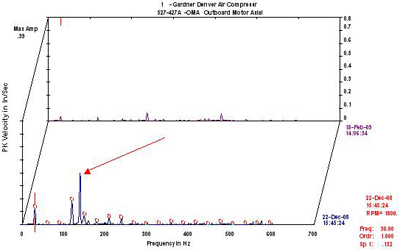

During testing, VAI collected and analyzed cross-channel phase data, which confirmed that the observed increase in vibration levels was attributable to an alignment issue affecting the turbine-driven feed water pump assembly. In response, we provided informal ODS (Operating Deflection Shape) training to the plant’s vibration engineer, empowering them with the knowledge and skills necessary to address the underlying alignment issue effectively.

Furthermore, recognizing the importance of ongoing monitoring and trend analysis, VAI installed a multi-channel vibration monitoring system at the plant. This system enables continuous monitoring of vibration levels across multiple points within the assembly, facilitating early detection of anomalies and proactive maintenance interventions.

By leveraging advanced analysis techniques and implementing robust monitoring solutions, VAI equipped the plant with the tools and expertise needed to safeguard against possible near-future issues, optimize equipment reliability, and ensure uninterrupted operation of the nuclear power plant.

The recommendations and data analysis services provided to the plant allowed them to continue operating until the next scheduled de-rate. At that time, they confirmed the problem was due to the loss of coupling lubricant, resulting in a bound coupling that adversely affecting the alignment.