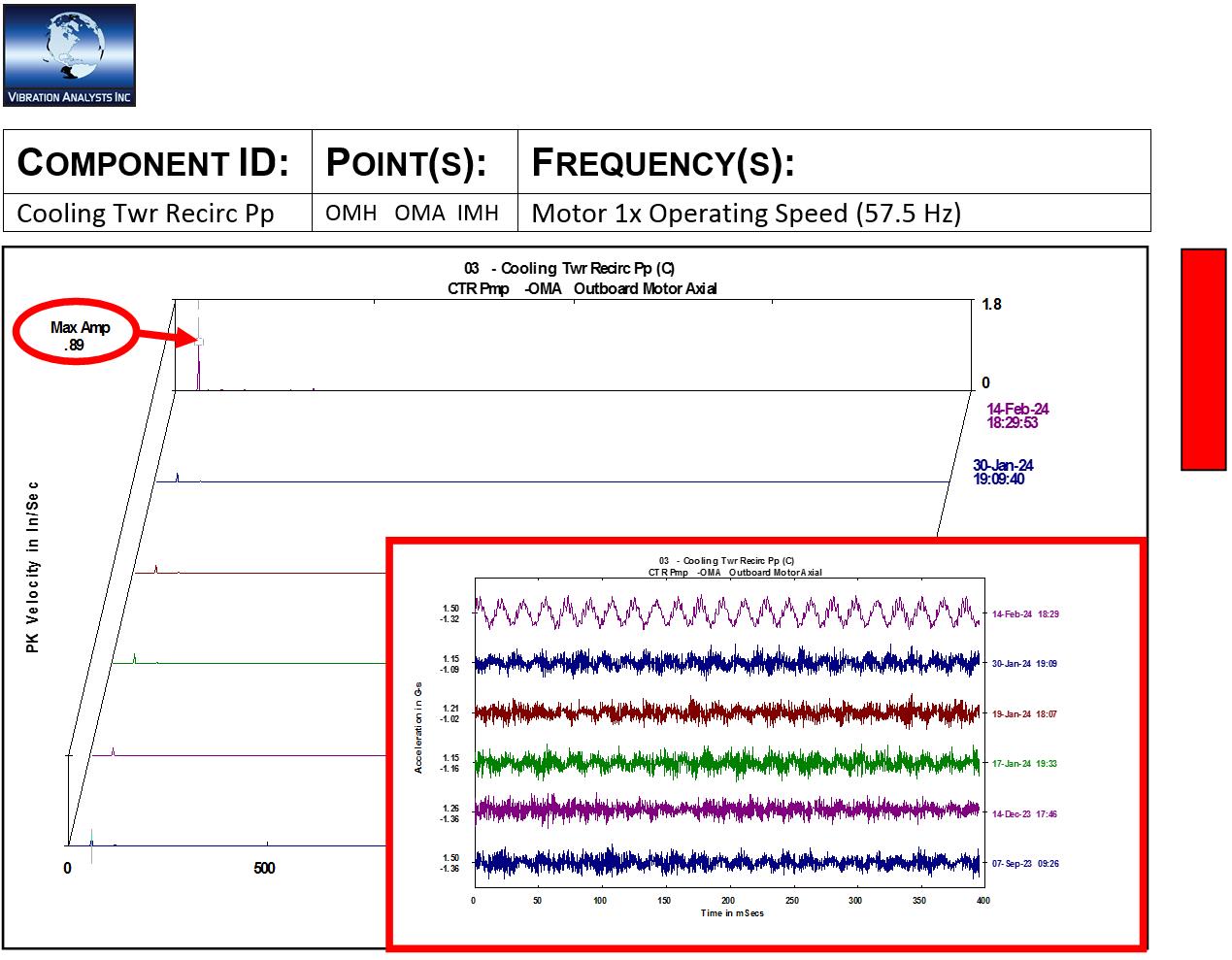

–Pump suction pipe resonating due

to location of vertical pipe support.

–Pump suction pipe resonating due

to location of vertical pipe support.

Our Vibration Testing Company specializes in Condition-Based Maintenance and Reliability-Centered Maintenance Programs.

Our Vibration Testing Services are designed to support Proactive Maintenance strategies by utilizing advanced Condition-Based Monitoring techniques and state-of-the-art test equipment to predict and prevent equipment failures.

Our teams of Maintenance Reliability Engineers and Certified Vibration Analysts are fully qualified and experienced providing cost effective condition-based maintenance solutions tailored to your specific needs.

Connect with our Maintenance Reliability Engineers today to find out how we can enhance your Maintenance and Equipment Reliability Programs with our condition based monitoring solutions, data analysis services and technical training.

Call us now at 815-742-1793, or for more information about our Vibration Testing Services, refer to the links below.

Ray W. Rhoe is President of Vibration Analysts, Inc.

Ray graduated from The Citadel in 1978 and obtained a Professional Engineer’s License. He started working in a “Noise and Vibration Group” at an east coast shipyard responsible for building and overhauling US Navy nuclear submarines. Ray later became the company’s Pump Component Engineer and then transferred to a large nuclear power utility working as their Pump Component Specialist. By combining his pump and vibration experience, and by attending several advanced vibration training courses, Ray worked his way up to be the Plant’s Vibration Engineer. While working in the nuclear industry, Ray completed a large Operating Deflection Shape Test (ODS) test on a 1250-megawatt Turbine Generator and two (2) elevations of the Main Turbine Building. Ray’s experience also includes precision balancing, troubleshooting component and structural resonances, and providing ISO Vibration Certification Training (Categories I, II and III).

Ray started working as an Independent Vibration Consultant in 2001, and shortly after he patented his data analysis process. After recognizing the many benefits of this patent, Ray incorporated his business and we became “Vibration Analysts Inc”. It’s who we are; it’s what we do!

Jeff E. Scott, PE., ISO Cat. IV Analyst

Jeff E. Scott is a Senior Vibration Consultant with VAI and our future President. Jeff graduated from Gonzaga University in 1999 with a B.S. in Mechanical Engineering and while working as an engineer for the Hanford Nuclear Energy Site, he also completed an M.S. in Mechanical Engineering from Washington State University in 2006. Jeff has a Professional Engineer’s License and a Category IV Vibration Certification with the Vibration Institute.

Jeff’s related experience includes the vibration analysis of radioactive casks and Finite Element Analysis of the effects of vibration energy on medical tooling. From 2007-2013 Jeff worked for a large nuclear power utility as their Plant Vibration Engineer and gained significant experience solving many different types of machinery vibration issues. During this time, he also attended several vibration related training courses and acquired industry certifications in Vibration Analysis, Lubrication Analysis, and Thermography. During this time, Jeff also became the plant’s Predictive Maintenance Program Owner with oversight and leadership over all predictive maintenance technologies.

In 2013, Jeff joined VAI and continued his growth and development and is now an experienced and Certified ISO Category IV Vibration Analyst working for VAI. He is also in-line to become our next President.

Our teams of ISO Certified Vibration Analysts offer exceptionally accurate results when analyzing machinery vibration data. As a leading Vibration Analysis Company, we provide comprehensive services including periodic and one-time emergent data analysis. Our Vibration Specialists are not only ISO Certified Vibration Analysts, but are also industry-recognized experts in their field.

Discover how our Vibration Analysis Company can help you achieve optimal machinery reliability for your entire plant. Our Vibration Analysis Services use state-of-the-art techniques and the industry’s best-rated vibration test equipment, ensuring both accurate and affordable results.

Clients consistently recognize our Vibration Analysts for their thorough and accurate analysis of their data. Reach out to our Certified Vibration Analysts today to find out how we can address your vibration analysis needs.

Call us now at 815-742-1793 or for more information, refer to the links below.

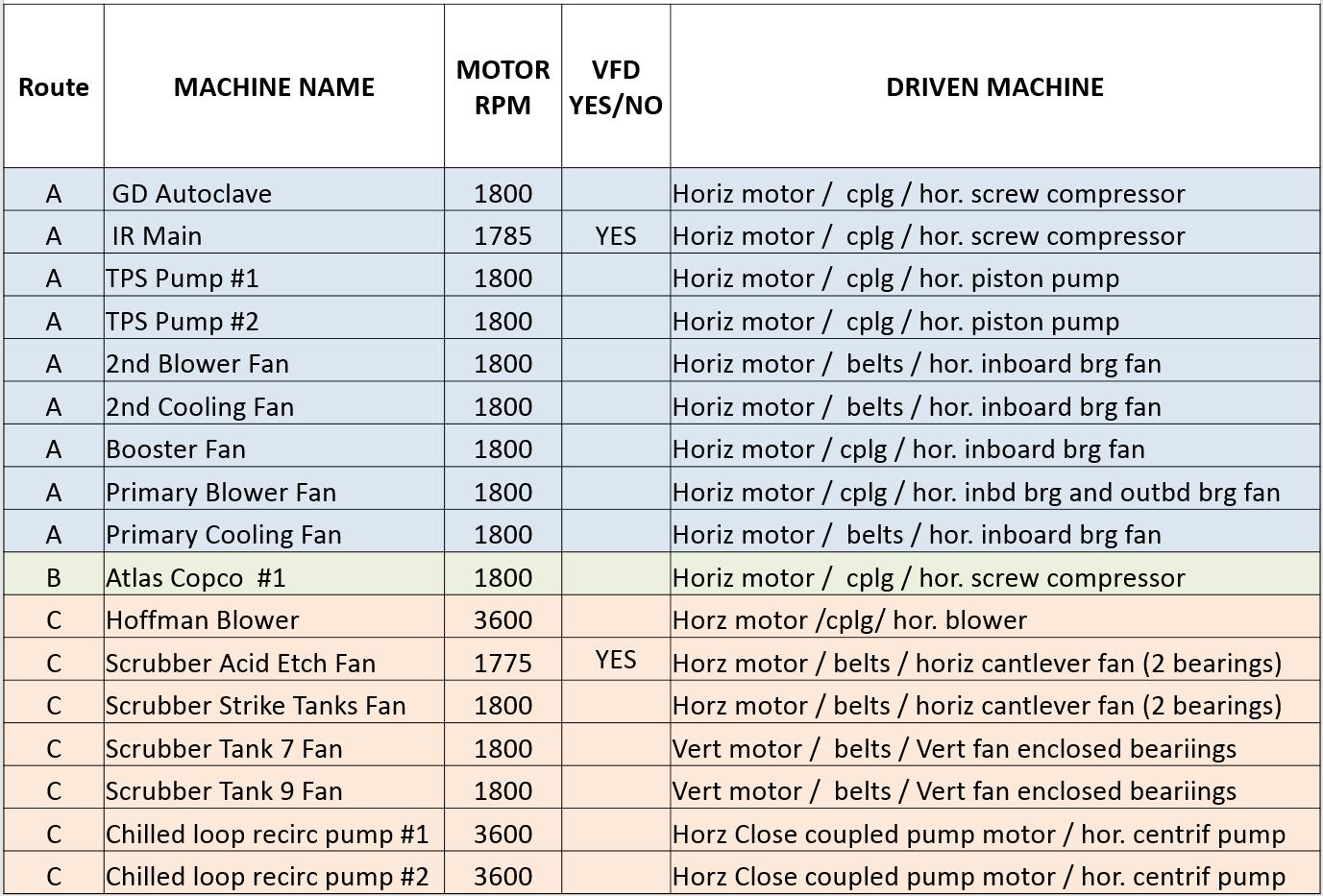

The equipment registration sheet (see image above) provides the machine information needed to accurately build a database for all machines. This information provides us the data we need to accurately assign all data analysis parameters which are needed to support an accurate data analysis. This information needed includes:

Expedite the collection of five (5) datasets, daily if possible. Why you ask:

After the initial five (5) datasets just collect data monthly and send to us for analysis. That’s it!

Call us for an emergent data analysis of the data. Just collect it and give us a call! We can usually respond in less than 2-hours.

We’re fully committed to supporting your machinery vibration program and when you have a machinery vibration problem, it’s also OUR problem until it has been resolved to your satisfaction. We’re available 24/7 and you can reach us off-hours, weekends and on all holidays. At VAI we every machine to be a ‘client’ and when any machine has a vibration problem, it’s also OUR problem!

The cost for each machine analysis is $ 500 USD and we gladly accept Credit Cards (VISA, AMEX and MASTERCARD) to expedite the process. Just email us the screen prints of your data and a few photos of the machine-train. Our Technical Support personnel are at VAI@infowest.com and vaiuser@vibrationanalysts.com. Be sure to include the following data, a summary of the machine’s problem, and any information that may be relevant.

Remember, the accuracy of our analysis depends on the quality and completeness of your data, and although we may ask for additional data, there will only be a one-time charge for our analysis.

We provide FREE on-site Data Collector Training to clients who have us analyze the data for of 30 or more machines per month for 12 months. This training is completely FREE; there are no travel, labor or other fees associated with this training.

Training topics include personal safety, setup and the use of the industry’s leading test equipment, determining the best machine test point locations, how upload new routes and download data. After the classroom training has been completed, the students proceed into the plant to collect their initial data while VAI mentors and monitors them. This service is totally FREE for clients who have us analyze their data.

VAI provides FREE database and route creation, maintenance and optimization services. That’s because it can be very time consuming and challenging for new users to create a database. Our Analysts know how to use the industry’s best software and which data analysis parameters are best for all types of machines. We can also build a large database with up to 300 machines in as little as a week.

For more information about our VIBRATION DATABASE MANAGEMENT services, refer to the link in our “Services” page.

We provide FREE 24/7 technical support in all areas. This means that if you ever have a machinery vibration issue (off-hours, weekends, holidays) just collect the data and email it to us for an accurate analysis. And if we can help in any other way, just call us at 815-742-1793.

We provide all clients with FREE 24/7 access to their database (read only) so they can login and view their data at any time. A tutorial on how to use the software is included.

To begin the process, just call us at 815-742-1793.

Test Equipment: Sales, Service, Rentals and Loaners:

New Sales:

We provide the BEST PRICES for CSI 2140 hand-held vibration meters and standard accessories (the industry’s standard!). For current pricing call us at 815-742-1793.

Rental Units:

Long term rental units (over a month) are available for use and evaluation before buying. This supports companies who do not have readily available funds to purchase a meter, or when their meter is in the repair shop, or for those who just need to ‘catch-up’ on their data analysis. Pricing includes the meter and all standard accessories included in a hard-shell protective case, less shipping. Meter’s are also setup and shipped with the Route installed.

The rental period starts and ends the same day of each month from when the meter was shipped. After one (1) full month the rental cost is pro-rated based on the number of days of each month until the meter is received by VAI.

Loaners:

FREE short term loaners (up to one month) are available for our established clients; just pay shipping. We’ll get one out the door all setup and with all standard accessories! The standard rental fee will apply (as noted above) if the meter is not returned within the month of the shipping date.

As a full service Vibration Testing Company we provide comprehensive database management services.

Using CSI’s AMS Machinery Health Manager Software, we create, maintain and optimize databases and routes.

For more information about these services, call us at 815-742-1793.

We build and maintain accurate databases and routes for clients worldwide.

We have built over 100 databases to date, many with over 300 machine-trains. We ensure all database parameters are correct based on the type of machines and their operating speeds. This includes: Fmin, Fmax, Lines of Resolution, Number of Averages, Waveform Parameters, Window Type and more. We also ensure all test points are included and the routes are ready to support the data collection process.

STEP 1: Provide a spreadsheet of all machines with the following data:

Our testing and troubleshooting services meet the most stringent industry standards, guaranteeing unparalleled accuracy and professionalism. We provide a comprehensive insight into the condition of your machinery, structures, and piping systems. We only use state-of-the-art test equipment and our patented data analysis process to deliver the most accurate data analysis results possible. At VAI, our core service is ACCURATELY analyzing machinery vibration data. If we didn’t, we’d have gone out of business at long time ago.

Machinery Performance Optimization:

By using VAI’s vibration testing services, you can gain insights into many machinery health conditions. This includes machinery reliability, performance, efficiency, and alignment. By optimizing machinery operating conditions, clients can improve energy efficiency, reduce operational costs, and enhance operating life and reliability to the plant.

Root Cause Analysis:

VAI’s vibration testing services are not only instrumental in detecting machinery issues but also in facilitating in-depth root cause analyses for clients. By accurately identifying and addressing the root cause of failures, clients can effectively prevent recurring problems, thereby maximizing the long-term operating life and reliability of their equipment to support uninterrupted plant operations. This proactive approach not only minimizes downtime and associated costs but also enhances overall operational efficiency and ensures sustained productivity in the long run.

Machine Acceptance and Baseline Testing:

VAI’s vibration testing services are tailored to support client maintenance strategies by taking into account the unique characteristics of their machinery. By leveraging our experience with our vibration testing services, clients can optimize the effectiveness of their maintenance activities while simultaneously minimizing costs and downtime. Whether it’s predictive, preventive, or proactive maintenance, our comprehensive analysis helps clients make informed decisions and prioritize actions to ensure optimal performance and reliability of their equipment. This strategic approach not only enhances operational efficiency but also fosters a proactive maintenance culture, ultimately driving long-term cost savings and maximizing asset up-time.

Risk Mitigation:

By determining the normal vibration levels and frequencies of critical components under normal operating conditions, VAI can quickly detect and identify any degradation due to wear, abnormal operating conditions, and improper or incomplete maintenance. By proactively addressing these changes, VAI can help prevent irreparable machinery damage or failures.

Compliance with Industry Guidelines:

VAI’s vibration testing services aligns with established industry guidelines and best practices. By adhering to these industry ‘expectations’, we ensure your machinery or structures adhere to pertinent safety and reliability standards, enhancing overall operational integrity. We have also ‘raised the ladder’ when it comes to classifying rolling element bearing defects based on their waveform impact levels and the fact that rolling element bearings degrade at an increasing rate. We’re also working on a classification chart for bearings that are operating with ‘ball skid’ type of defect.

Before a new or rebuilt “high-dollar” machine leaves a suppliers facility, you should have it tested to verify it meets all Purchase Order and Specification requirements. This test is called an “Acceptance Test”.

Although a supplier may be able to perform an Acceptance Test, due to a conflict of interest it’s always best for your Analyst or an independent test agency to perform this testing.

Our Category IV Analysts are highly trained and qualified to perform Acceptance Testing. During an Acceptance Test, we ensure the machine is operated at specified test conditions before collecting the data. We also witness all parts of the test; we verify the supplier’s gauges and instrumentation are calibrated and that all specified test conditions (pressure, dP, temperature, load, etc.) are met.

After the test data has been analyzed, we provide a detailed report which includes all test data, photos (as allowed), the test results, conclusions and recommendations.

To schedule VAI to perform an “Acceptance Test” on your behalf, call us at 815-742-1793.

Upon receipt of a new/rebuilt machine, it should be first tested “uncoupled” in the ‘motor shop’ before installation. This is to confirm the motor bearings are still in good condition and no damage to internal components occurred during shipping (loading, unloading and transportation).

The uncoupled run should measure the waveform impact levels, which should not exceed 1 g’s-Pk. If they do, the bearings were likely brinelled during transportation and should be replaced prior to installing the machine in the plant.

After installing in the plant, a “Baseline Test” is performed. The machine is started and data immediately collected to ensure the levels are not excessive due to improper installation. Data is also collected while system operating conditions are adjusted to ensure the machine doesn’t have a developing issue and, after the machine has reached normal operating conditions, a final set of data is collected. This is the “Baseline” data upon which all future data is compared.

For assistance with collecting Baseline Data and troubleshooting any vibration issues, please call us at 815-742-1793.

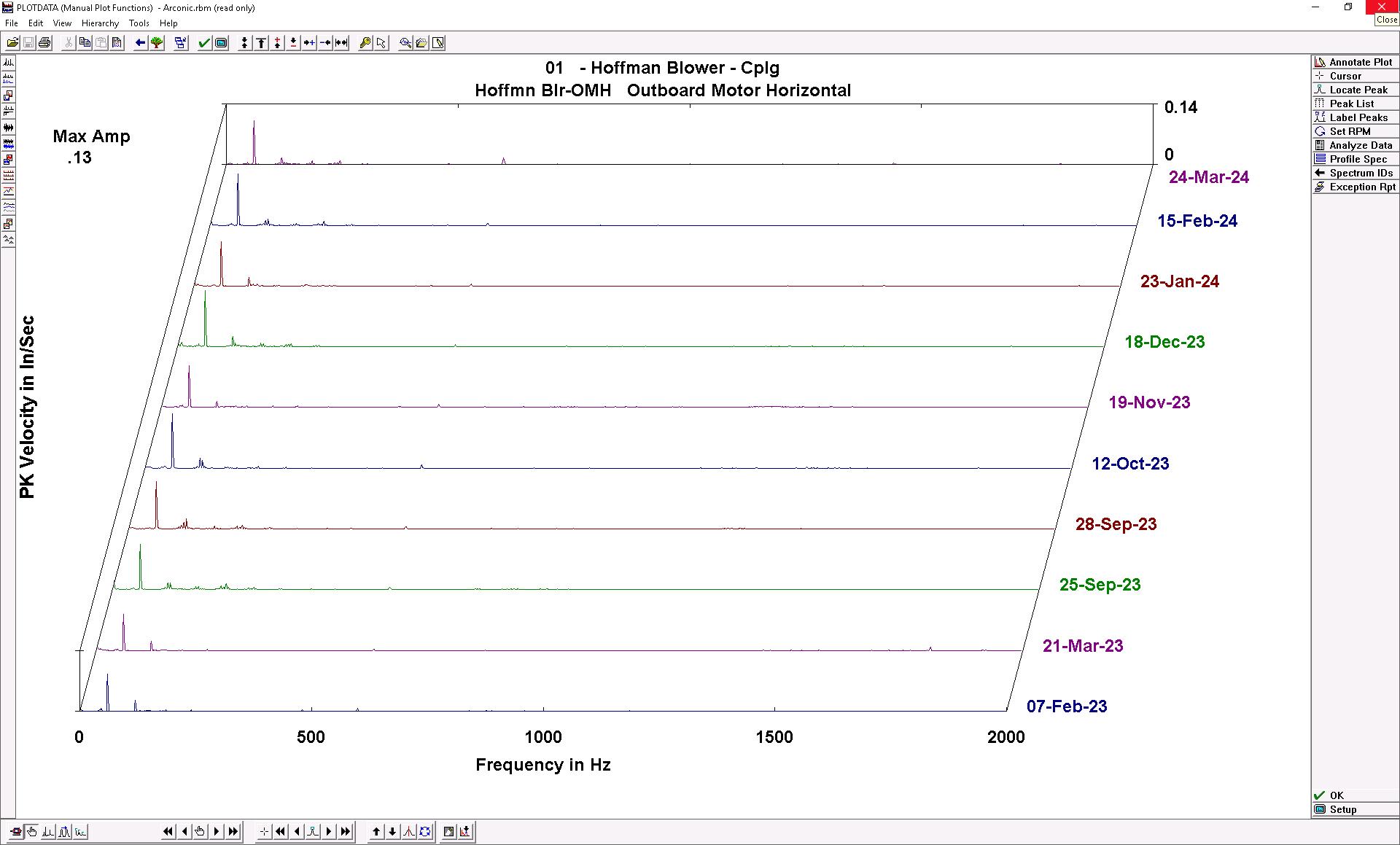

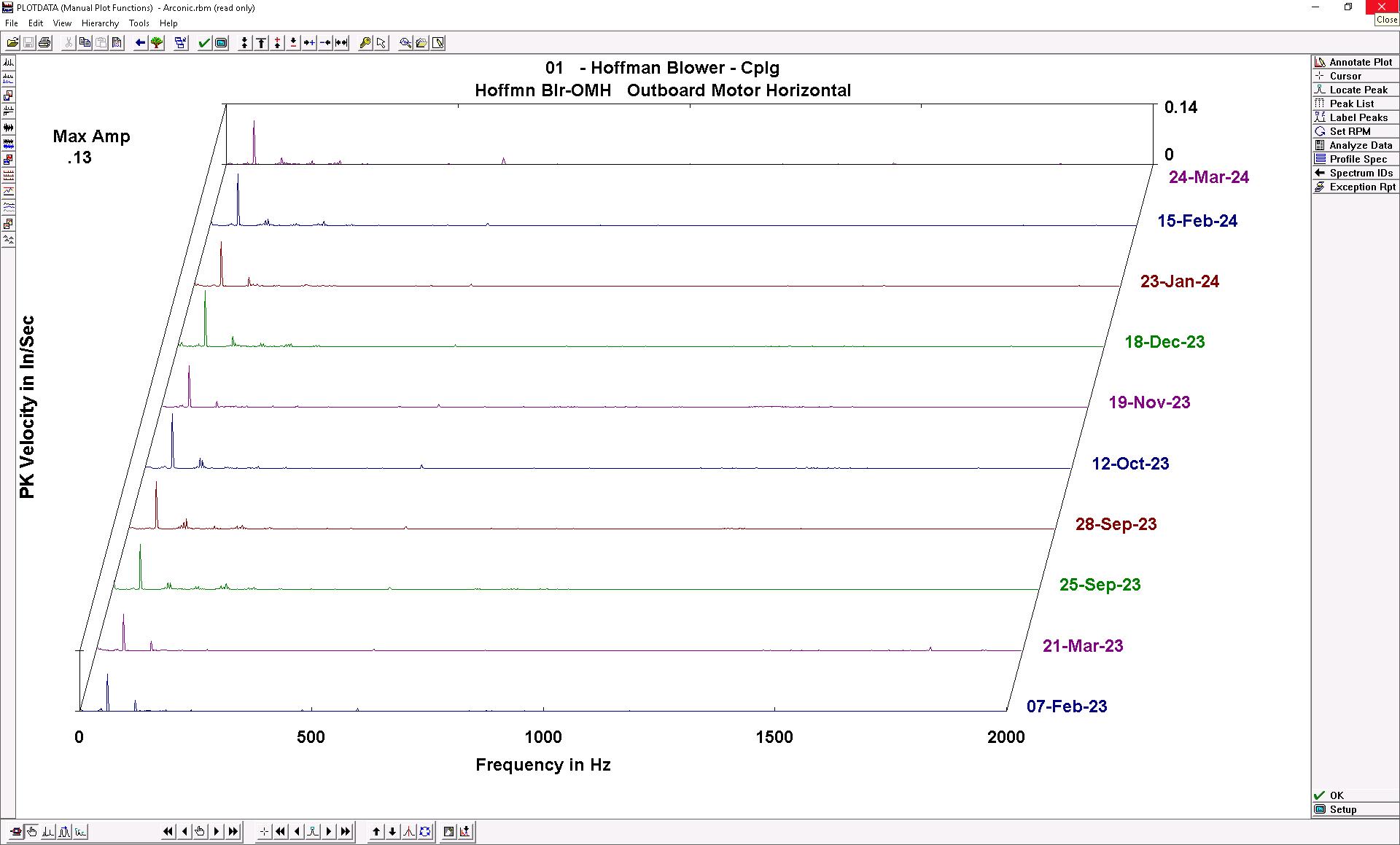

Periodic test data is collected on a regular basis so the health of all critical, essential and high-dollar machines can be monitored over time.

Periodic testing consists of collecting route-based data on monthly basis (recommended). This frequency is recommended by the industry because rolling element bearings can progress from a ‘good’ condition to ‘bad’ in as little as 45 days. Monthly trending will catch these issues.

Route-based data collection is exceptionally easy to perform; it’s the data analysis that requires highly trained, experienced and knowledgeable Analysts.

For help with your data analysis, call us at 815-742-1793. All you have to do is collect the data.

Yes it’s THAT easy!

It happens. Everything was fine but now the vibration data shows a step increase in the machine’s vibration levels, and they are now unacceptable.

What do you do? You could disassemble the machine and check everything (the ‘shotgun’ approach) only to put it all back together and find out you still have a vibration issue. This would a good time to call us.

Our ISO Category IV Analysts can quickly analyze the data and support emergent issues just like this. To get an emergent analysis of your data, or one of our Cat. IV Analysts on their way to your plant, just call us at 815-742-1793.

Our multi-channel testing services include the ability to continuously record very high resolution waveform data on up to 16 channels and for several hours in duration. This testing can support data collection across an entire machine while the system’s operating conditions (temperature, pressure, load and rpm) are varied.

One example where this testing would be useful, would be in placing several sensors evenly spaced on a pump’s recirc line to determine if a resonance was present, and the location of the anti-node(s) which are points of maximum vibration amplitudes.

ODS animation of a pump and the suction piping vibrating at Vane Pass frequency

Our ODS testing services provide hidden insights into structural dynamics, resonant frequencies and mode shapes. This testing enables us to identify issues such as mechanical weakness, excessive flexibility, bending modes, and more.

ODS testing involves collecting data while a machine is in operation. On the other hand, Modal Analysis requires a data collector to generate the machine’s vibrations by using an ‘impact’ hammer, which can be labor intensive.

The results of these tests provide a visual 3-D animation showing how a machine moves in real time at any frequency, often revealing a weakness in the design.

For support and testing, call us at 815-742-1793.

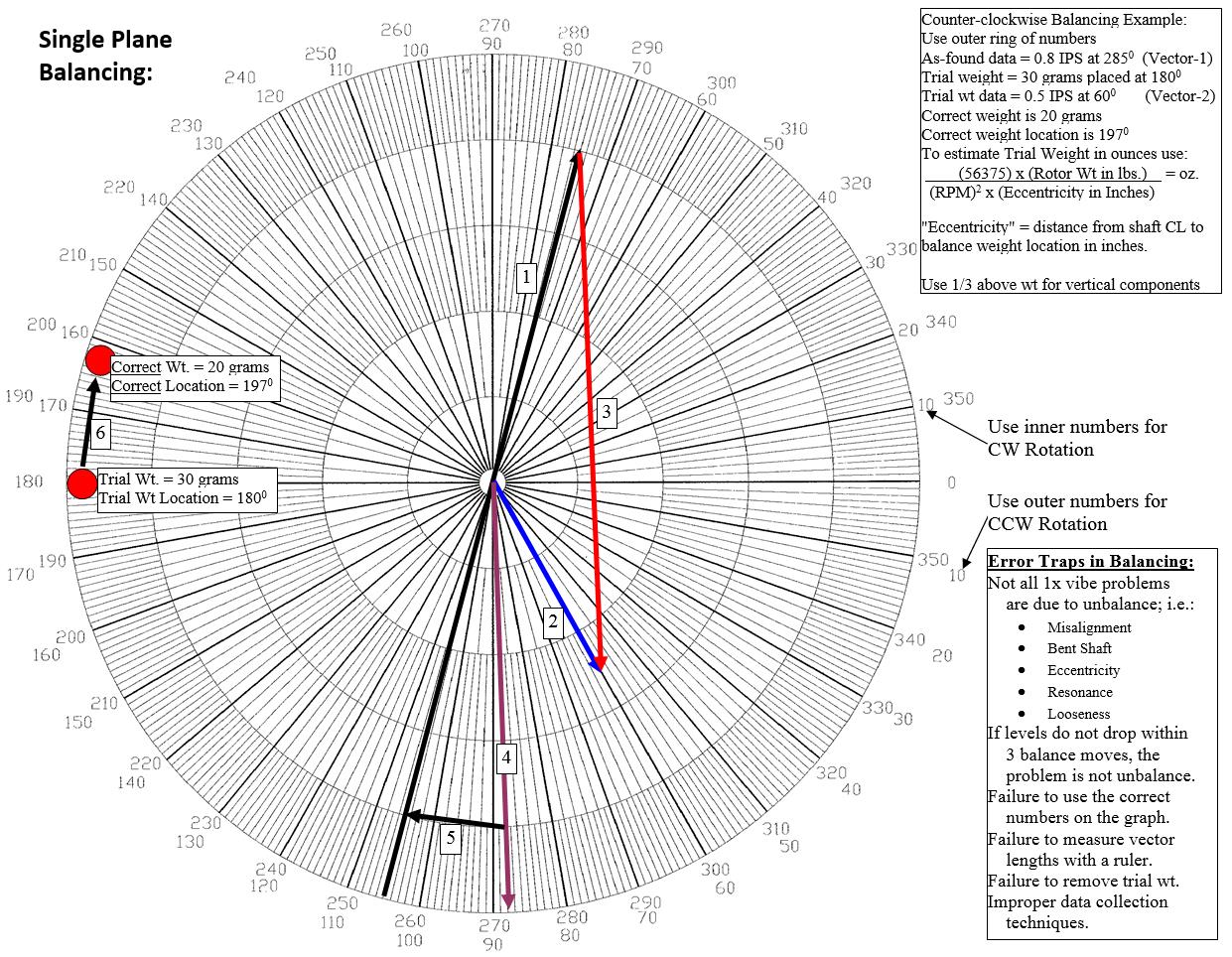

Our Vibration Analysts can perform on-site single plane fan balancing. Balancing is usually needed when amplitudes get too high at 1x operating speed. In nearly all cases, the radial vibration levels will be noticeably higher than the axial levels.

There is no need to purchase expensive vibration test equipment or balancing software; our Vibration Analysts do everything except “turn wrenches” … due to insurance restrictions.

VAI strongly recommends against untrained staff performing balancing moves because the kinetic energy of a balance weight (if it comes off) can cause personal injury or death.

To schedule on-site single-plane balancing, call us at 815-742-1793.

VAI’s core business is analyzing machinery vibration data worldwide. To ensure accurate results, we ONLY use the Industry’s best vibration test equipment and software all made by Emerson / CSI. We strongly recommend CSI’s products but don’t take our word for it. Go to an industry industry vibration conference and ask for a “show of hands” of “who uses CSI’s products?”. The response will probably be greater than 70%.

At VAI, we ONLY recommend and sell what we use for our livelihood, and we only use the industry’s best test equipment and software made by CSI.

For clients looking for the absolute best price on the industry’s best-rated hand-held vibration test meter, we offer substantial discounts to clients who select us analyze their vibration data. And as part of our service, we provide FREE on-site Data Collector Training so that your staff can begin immediately collecting data.

Need to get caught up? Want to evaluate before buying? This may be the best option for a company who wants to try CSI’s best-rated vibration test equipment before buying. We also rent to companies who need a rental unit while their meter is being repaired and those who need to ‘catch-up’ on their data analysis.

We provide FREE loaners to clients who have us analyze the data for a minimum of 30 machine-trains a month for one (1) year. These loaners are available when client meters are being re-calibrated, repaired, or when another meter is needed just to get things “caught-up”.

“Their analysis provided unparalleled accuracy in identifying real machinery issues.”

“They can accurately detect and identify vibration issues at the earliest possible stages.”

“Our equipment’s reliability has improved significantly during their watch.”

“VAI’s services continue to optimize the health and reliability of our machines.”

“Very impressed by VAI ‘ONLY’ using state-of-the-art test equipment like the CSI’s vibration meters.”

“Their patented data analysis process is doing a terrific job. Very accurate!”

“VAI’s Certified Vibration Analysts have exceptional knowledge. Not only are they expert vibration analysts, but they also have a solid understanding of how machines are designed and built.

“Their analysts perform different parts of the analysis based on their knowledge and experience. This allows ‘the team’ to accurately analyze and process exceptionally large quantities of data within 24 hours.”

“They go beyond just identifying issues; they also provide an accurate list of the possible causes, prioritizing the most likely first, and providing accurate corrective recommendations.”

“Their approach covers all aspects, ensuring nothing is overlooked. And if it were, I’m confident they would modify their approach to making it better!”

“Quick and timely identification and resolution of vibration-related problems.”

“Their services help us address issues before they turn into major problems.”

“VAI established very clear and professional communication at the start of our program; very easy to work with.”

“Their services had a positive impact on our overall operational efficiency. They are even able tell us when we have too many (or too few pumps running) just based on the vibration data!”

Our machinery downtime has gradually decreased since VAI has been analyzing our data, and we continue to substantial return on investment as we continue to optimize our vibration program.

The above are just some of the ways VAI can help you with your vibration program.

To learn how we can meet your data analysis and program needs, call us at 815-742-1793.

“Their analysis provided unparalleled accuracy in identifying real machinery issues.”

“They can accurately detect and identify vibration issues at the earliest possible stages.”

“Our equipment’s reliability has improved significantly during their watch.”

“VAI’s services continue to optimize the health and reliability of our machines.”

“Very impressed by VAI ‘ONLY’ using state-of-the-art test equipment like the CSI’s vibration meters.”

“Their patented data analysis process is doing a terrific job. Very accurate!”

“VAI’s Certified Vibration Analysts have exceptional knowledge. Not only are they expert vibration analysts, but they also have a solid understanding of how machines are designed and built.

“Their analysts perform different parts of the analysis based on their knowledge and experience. This allows ‘the team’ to accurately analyze and process exceptionally large quantities of data within 24 hours.”

“They go beyond just identifying issues; they also provide an accurate list of the possible causes, prioritizing the most likely first, and providing accurate corrective recommendations.”

“Their approach covers all aspects, ensuring nothing is overlooked. And if it were, I’m confident they would modify their approach to making it better!”

“Quick and timely identification and resolution of vibration-related problems.”

“Their services help us address issues before they turn into major problems.”

“VAI established very clear and professional communication at the start of our program; very easy to work with.”

“Their services had a positive impact on our overall operational efficiency. They are even able tell us when we have too many (or too few pumps running) just based on the vibration data!”

Our machinery downtime has gradually decreased since VAI has been analyzing our data, and we continue to substantial return on investment as we continue to optimize our vibration program.

The above are just some of the ways VAI can help you with your vibration program.

To learn how we can meet your data analysis and program needs, call us at 815-742-1793.

“Their analysis provided unparalleled accuracy in identifying real machinery issues.”

“They can accurately detect and identify vibration issues at the earliest possible stages.”

“Our equipment’s reliability has improved significantly during their watch.”

“VAI’s services continue to optimize the health and reliability of our machines.”

“Very impressed by VAI ‘ONLY’ using state-of-the-art test equipment like the CSI’s vibration meters.”

“Their patented data analysis process is doing a terrific job. Very accurate!”

“VAI’s Certified Vibration Analysts have exceptional knowledge. Not only are they expert vibration analysts, but they also have a solid understanding of how machines are designed and built.

“Their analysts perform different parts of the analysis based on their knowledge and experience. This allows ‘the team’ to accurately analyze and process exceptionally large quantities of data within 24 hours.”

“They go beyond just identifying issues; they also provide an accurate list of the possible causes, prioritizing the most likely first, and providing accurate corrective recommendations.”

“Their approach covers all aspects, ensuring nothing is overlooked. And if it were, I’m confident they would modify their approach to making it better!”

“Quick and timely identification and resolution of vibration-related problems.”

“Their services help us address issues before they turn into major problems.”

“VAI established very clear and professional communication at the start of our program; very easy to work with.”

“Their services had a positive impact on our overall operational efficiency. They are even able tell us when we have too many (or too few pumps running) just based on the vibration data!”

Our machinery downtime has gradually decreased since VAI has been analyzing our data, and we continue to substantial return on investment as we continue to optimize our vibration program.

These are just some of the ways VAI can help your vibration program. To learn how we can meet or exceed your data analysis and program needs, call us at 815-742-1793.