-

Equipment Health Monitoring

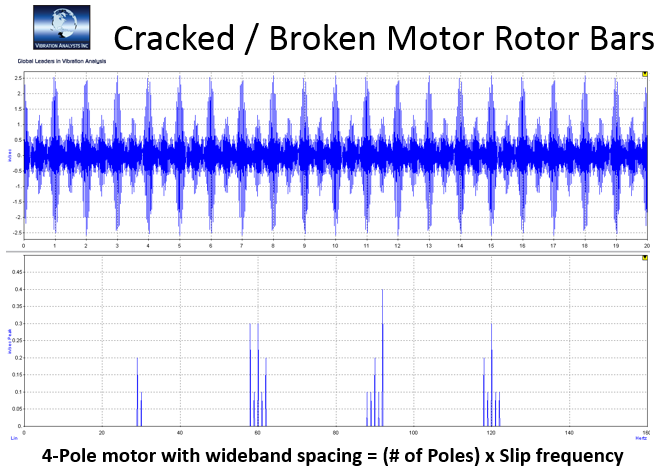

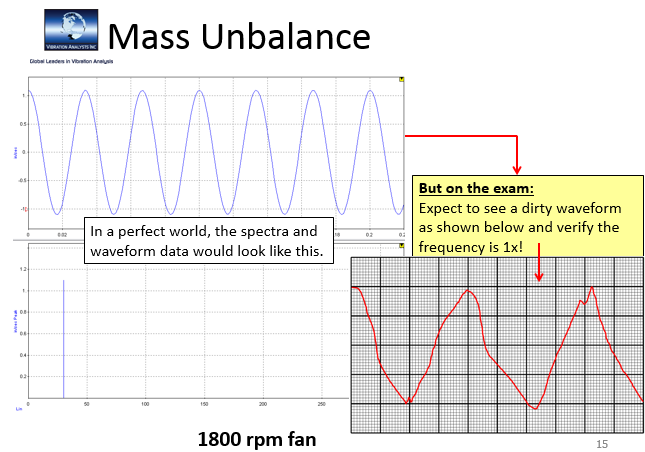

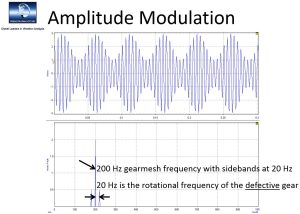

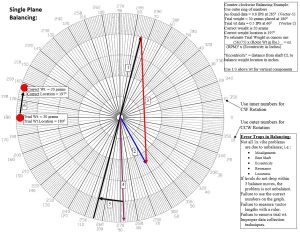

After attending a Vibration Analysis Training course, students will be better able to detect and identify changes in the vibration data which point to degrading machinery conditions. These conditions include misalignment, unbalance, bearing wear, and numerous other mechanical problems. By being able to detect and identify these issues at the earliest stages of development, corrective maintenance can be scheduled and performed to prevent machinery failure.

-

Predictive Maintenance

Predictive Maintenance employs Vibration Analysis Training as its primary technology for detecting and identifying equipment degradation proactively. This approach allows maintenance teams to intervene with corrective measures before machinery failure occurs. By implementing timely actions, Predictive Maintenance not only prevents costly breakdowns but also enhances machinery performance and reduces maintenance expenses.

-

Energy Efficiency

Machines that are out of alignment, significantly unbalanced, and pumps that are operating well off their Best Efficiency Point will consume additional energy. Machine Vibration Training provides staff with the knowledge to detect and identify these conditions which can be passed on to Operators so they can adjust system operating conditions as needed.

-

Personnel and Machine Safety

Excessive vibrations can be a safety hazard, but by attending Vibration Training Courses

Analysts gain knowledge on how to identify and address issues that could lead to equipment failure or pose risks to personnel. This proactive approach enhances workplace safety.

-

Quality Control

In manufacturing processes, the information gained by attending Vibration Analysis Courses can be indispensable especially for personnel responsible for ensuring product quality. By continuously monitoring vibrations during production, anomalies or defects in the manufacturing product can be swiftly identified, thereby preventing the production of faulty or degraded products.

-

Knowledge & Skill Development

Machine Vibration Training is indispensable for personnel responsible for maintenance and reliability engineering. This training provides staff the skills needed to use vibration analysis tools and accurately interpret the data. As a result, maintenance and reliability staff are better equipped to identify and address potential machinery issues.

-

Cost Savings

By attending one or more Vibration Training Courses professionals can implement preventive maintenance strategies rather than rely on reactive maintenance caused by a machine failure.

-

Comprehensive Curriculum

Vibration Training Courses provide a comprehensive understanding of machinery vibration issues, encompassing fundamental principles and introducing participants to the language of machine design, operation, and performance.

-

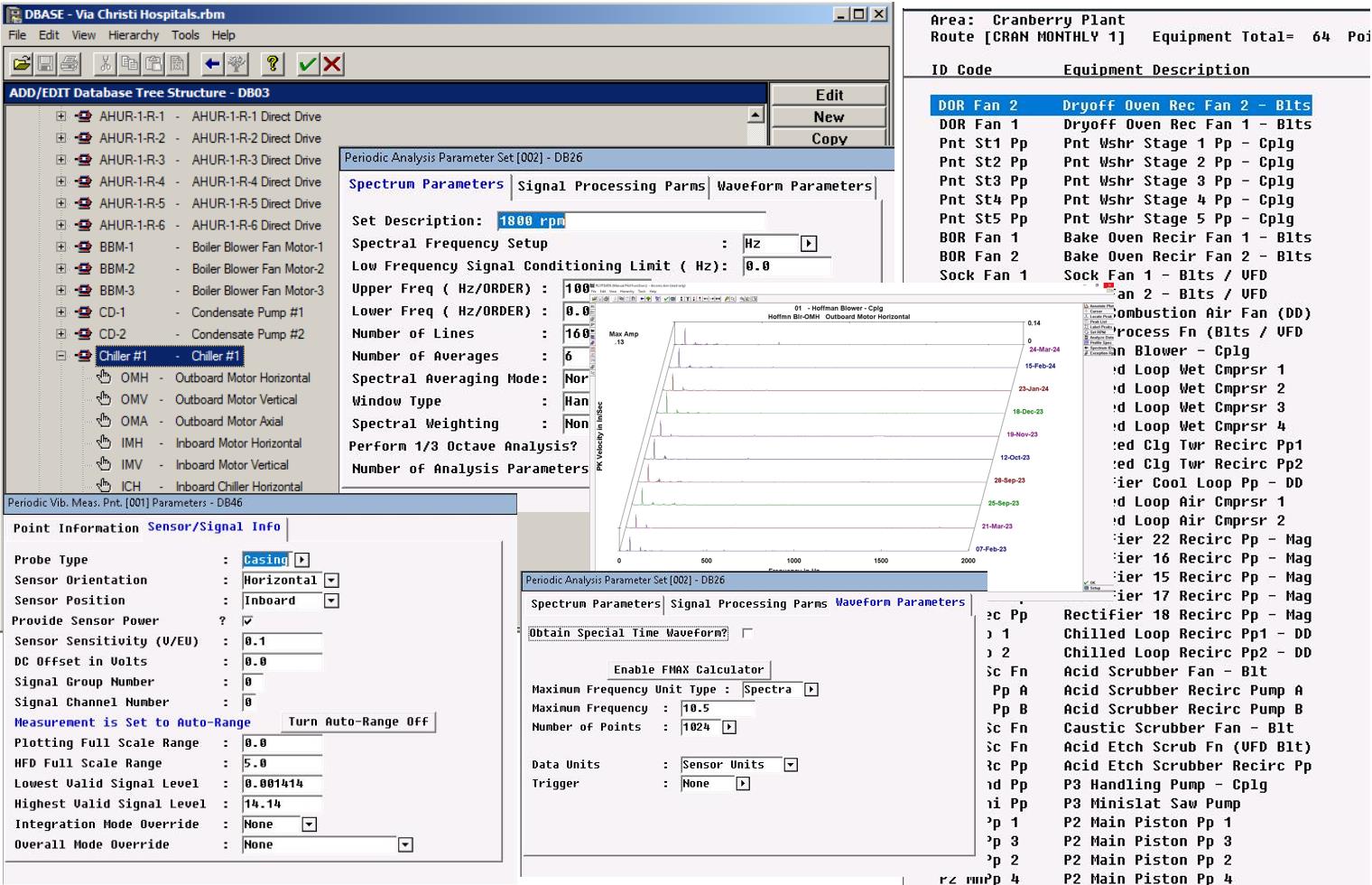

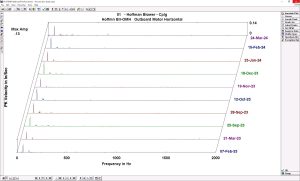

Practical Hands-On Experience

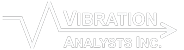

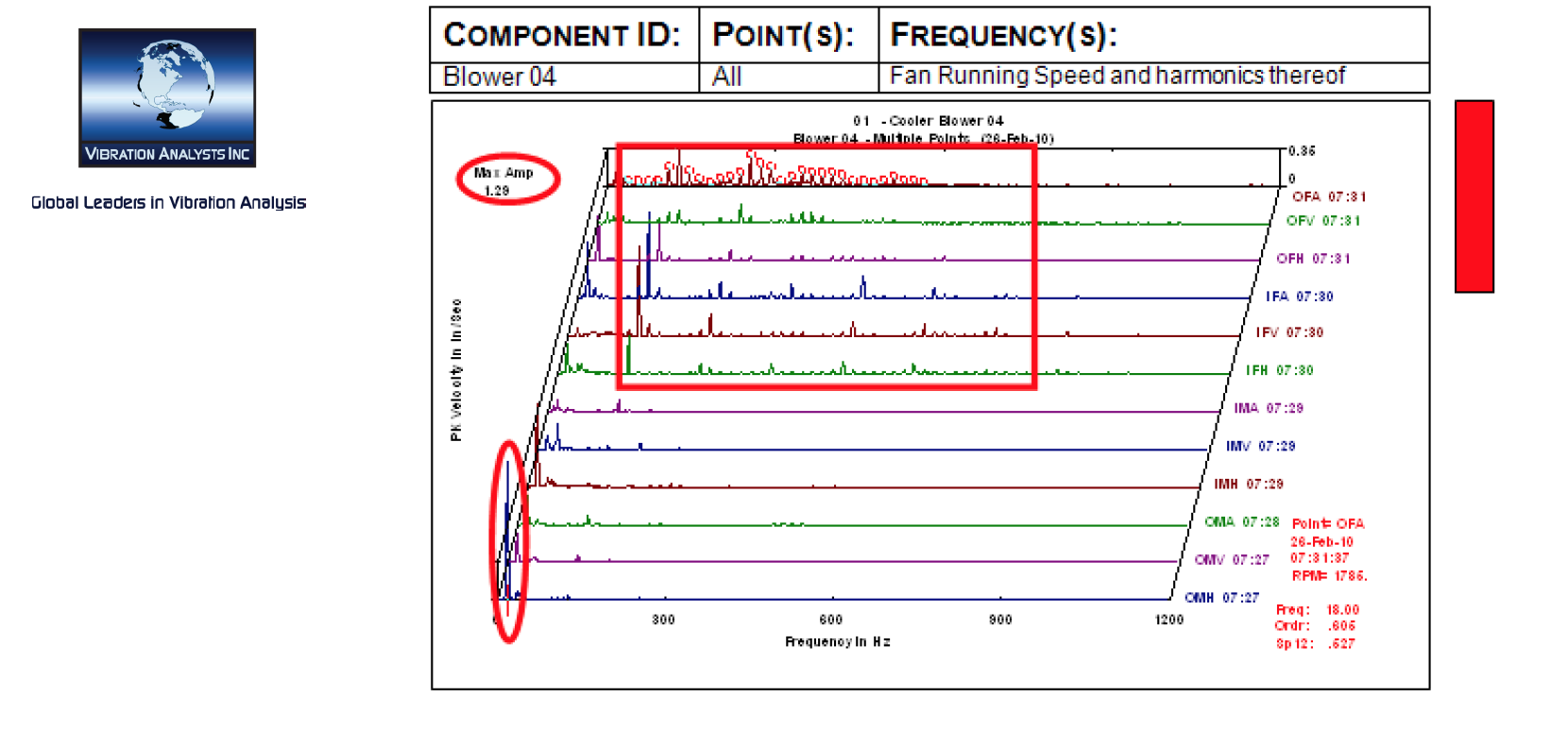

Mastery of vibration analysis at any ISO Category, requires practical Vibration Analysis Training, and our courses integrate real-world machinery vibration data into our training material. Our on-site Data Collector Training, when combined with ISO Category I or II Training, provides students the opportunity to collect and analyze their vibration data as part of new program startup activities. This hands-on approach allows us to mentor students as they both collect and analyze their data, empowering them to make informed decisions.

-

Industry Relevant Topics

We offer the flexibility to tailor our Vibration Analysis Training courses to the specific needs and challenges of our clients. Our courses address the more common machinery types, the typical issues associated with each type, and the recommended corrective actions.

-

Exposure to Advanced Tools and Techniques

Our training courses introduce students to state-of-the-art vibration analysis tools and technologies. Participants gain hands-on experience with the industry’s top-rated test equipment and software.

-

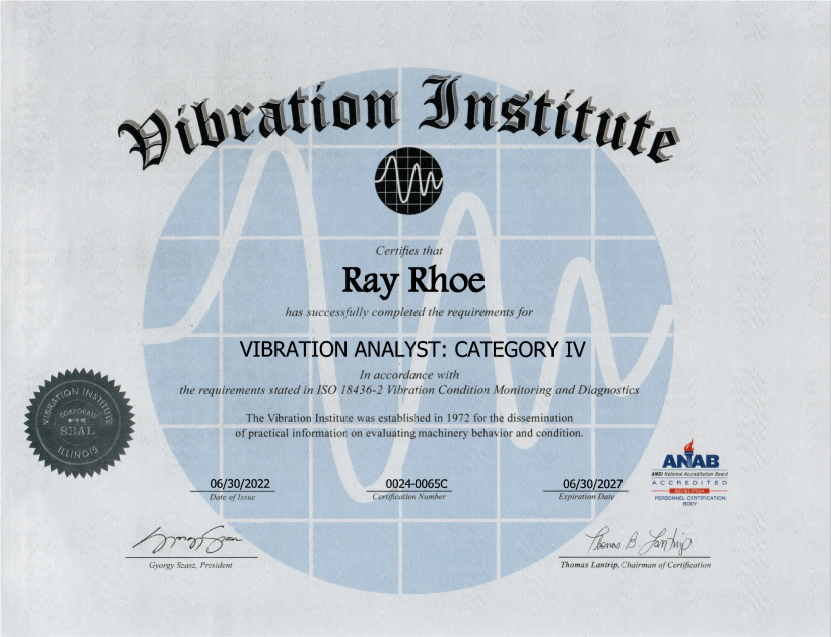

Instructor Experience

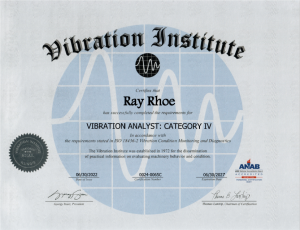

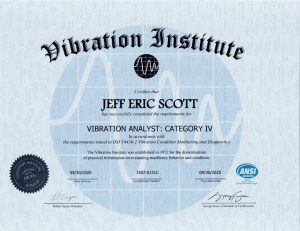

Did you know that by attending one of our Vibration Analysis Courses, your most serious and perplexing vibration problem could be resolved! We are committed to maintaining unparalleled quality and expertise of our instructors, and we exclusively enlist experienced ISO Category IV Certified Vibration Analysts, each having decades of practical experience.

-

Interactive Learning Environment

VAI’s Vibration Training Courses are comprehensive and we allocate time for students to interact and engage with each other. Our dynamic learning environment includes periods for group discussions, questions and answers, and collaborative problem-solving.

-

Industry Recognized Certification

Upon completing a Category I, II, or III Vibration Analysis Training course and passing the ISO Exam, participants receive an industry recognized certification. This certification not only adds credibility to the students’ knowledge and experience, but validates their proficiency in this technology.

-

Continuous Learning Opportunities

In the dynamic field of vibration analysis where the technology is ever-evolving, a machine’s vibration response to different defects will remain constant. Our courses follow a multi-tiered approach to training, preparing students to advance to higher levels of certification. While emphasizing continuous learning, our Vibration Training Courses stress the importance of building a technical library, attending webinars and keeping analysts informed about the latest advancements in their profession.

-

Case Studies

Our training courses incorporate real-world case studies, providing participants with practical examples in solving actual situations preparing them for the challenges they will likely encounter in the workplace.

-

Feedback and Self-Evaluations

During our training we use assessment forms, quizzes, and practice exams to keep participants engaged and pinpoint areas for potential improvement. As with any training course, we value and encourage constructive feedback by providing evaluation forms.