Machinery Vibration Data Analysis Services

Why Choose VAI? << Please make this a ‘drop down’ which includes the following paragraph and the 1-liner after it

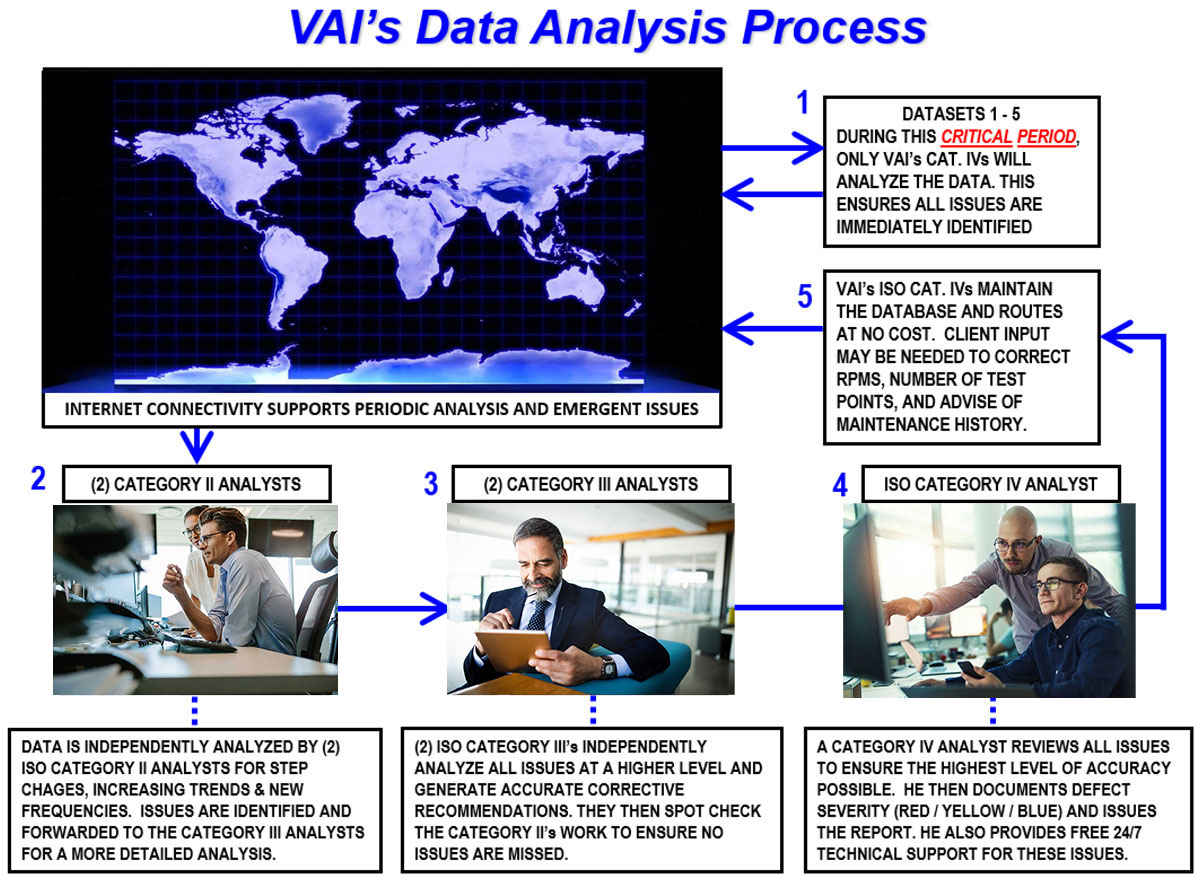

THE IMAGE AT THE TOP OF THIS PAGE IS THE OLD IMAGE AND SHOULD BE STANDARDIZED WITH THE HOME PAGE At VAI, our teams consist of ISO Certified Category II, III and IV Vibration Analysts who use our patented data analysis process to bring clients unparalleled accuracy when it comes to analyzing machinery vibration data. Every Analyst on our teams is ISO Certified Category II or higher, and must maintain their certification to remain with VAI. This guarantees precision and reliability with every aspect of our services which allows us to deliver accurate insights and tailored solutions to any client. Our teams of Certified Vibration Analysts offer unparalleled expertise while analyzing client machinery vibration data, because we patented the industry’s leading data analysis process. Our unique process ensures clients receive the highest level of accuracy and reliability attainable for any project. For example, up to five (5) ISO Certified Vibration Analysts analyze the data on three (3) levels of increasing knowledge and experience. At the ‘top’ of each team, an ISO Category IV Analyst performs the highest level of review possible, and provides a detailed report summarizing each machine’s reliability, corrective actions (if any) needed, and how soon the repairs should be made.

Experience the difference with VAI. Call us today at 815-742-1793.

-

Accurate Results! (<< drop down)

Our unique Data Analysis Process was granted a full US Patent, and by using it, we can create a complete and accurate vibration program for any client in as little as two (2) weeks (and most of that time is needed by the client to generate their list of equipment). Our patented process also allows us to provide many FREE benefits not possible with in-house programs. These include FREE on-site Data Collector Training (no travel or contractor fees), FREE 24/7 Technical Support by ISO Cat. IV Analysts, FREE Database Creation, Maintenance and Optimization, and FREE access to the Industry’s leading vibration database software. And that’s just a start.

Another reason for our success is that up to five (5) ISO Certified Vibration Analysts analyze the vibration data as an assembly line. In this assembly line, each Analyst analyzes the data according to their training, knowledge and experience. And by maintaining a highly experienced and diverse staff, we can offer clients FREE 24/7 technical support which means that whenever a machine develops a vibration issue (or something else) we’ll be here to help resolve the problem.

-

Estimated $6.38:1 Return on Investment! (<< drop down)

Our patented process allows us to efficiently, accurately and affordable analyze large quantities of data for a fraction of what clients can do in-house. As an example, one of our clients who has 45 plants across the US and Mexico reported a $6.38 ROI for every dollar spent on our services. References available!

-

Knowledge! Training! Experience! (<< drop down)

Our senior Analysts have the industry’s highest level of ISO Certifications and have decades of experience. Each team of Analysts has an average of 100 years of combined experience and they have seen just about every possible type of machine issue possible. DOD Radiated Noise Reports? Safety Related Components at Nuclear Power Plants? Industry one-offs and unique machines? Waveform analysis? ODS testing? No problem; we’ve just about seen everything possible and we’re confident we can help you.

-

More Expertise than NASA and US DOD. (<< drop down)

VAI also has more ISO Category IV Analysts than NASA and the US DOD … combined. Need help starting up a vibration program? Data analysis? Emergent Vibration Problem? 24/7 Technical Support? Call us now at 815-742-1793 and we’ll be glad to help!

Machinery Vibration Data Analysis

Our most sought after service is analyzing plant machinery vibration data for clients worldwide. Simply stated, we provide FREE on-site Data Collector Training to clients who then collect their data and email it to us. We then analyze the data, provide accurate corrective recommendations, and issue a detailed report. Our services are accurate, dependable, affordable (typically 1/3 the cost of doing the analysis in-house) and we provide FREE 24/7 Technical Support.

Our Vibration Specialists provide database creation, maintenance and optimization services. With the knowledge and experience our staff has, we can support small individual plants as well as corporate programs for multiple plants. Depending on the number of machines in the database, clients can easily save several thousand dollars before collecting the first set of data. Our services also include free database storage on VAI’s secure server and we provide clients FREE (read-only) access to their database.

Need help creating a standardized vibration program for multiple plant locations? We can standardizes all of the following program attributes:

- Data Collector Training

- Vibration Test Equipment and Software

- Vibration Data Analysis Process

- Vibration Database Construction and Format

- Appearance of the Vibration Reports

- Location of Vibration Test Points

- Efficient one (1) point of contact

- We offer clients the lowest prices on CSI’s test equipment and software

Our largest client has ~ 45 plants worldwide and we have standardized all aspects of their vibration program – references available – including all of the following FREE BENEFITS (<< this link should open to an index with the following items in it as drop downs) to clients who contract a monthly data analysis for 30+ machines over 12 consecutive months.

- FREE On-Site Data Collector Training

Our “Data Collector Training” course trains students on how to use the CSI 2130 / 2140 vibration meters so they can safely collect vibration data. Why pay contractor labor and travel expenses when your staff can easily and safely collect the data? With the proper training, data collection is safe and easy. During the training, VAI will monitor students for training proficiency and safety while they collect their first set of data on actual plant equipment. We’ll also ensure all test points are properly marked and in the best location possible. And for clients who choose to have VAI analyze their machinery data (30+ machines per month for 12 months) we will provide this training on-site for FREE; no training or travel expenses (zip!). We will also provide your staff with complimentary e-copies of our comprehensive “Data Collector Training Manual” that refer all aspects of the 2130/2140 meters.

- FREE Database Management

Our Vibration Analysts have created over 100 databases for clients worldwide, with some having over 300 machine-trains. Our Vibration Specialists know how to properly select the critical vibration parameters such as Fmin and Fmax, Data Resolution, number of data averages, window type, and test point locations. By selecting VAI as your business partner, you’ll not only start with an exceptionally accurate database and efficient routes, but we provide FREE 24/7 technical support.

- FREE 24/7 Technical Support

For clients who select VAI to analyze their machinery data (30+ machines per month for 12 months) we will provide FREE 24/7 technical support. This is the most highly valued benefit to most clients, because it means VAI will provide an unlimited FREE analysis of any emergent issues. For example, if an operator hears a machine making an odd noise, just collect the data and send it to us. We’re provide a FREE analysis of all covered machines and make changes to routes and / or databases as needed, Just call us at 815-742-1793 and we’ll be there to help you.

- FREE Vibration Database Access

We also provide FREE database access (read-only) so clients can view their vibration data at any time. Not only will you get accurate and detailed reports of all vibration issues, you can now view your data and compare it to the machine reports!

Program Startup Services:

FREE Loaner Meters: (<< drop down to the following)

VAI provides FREE loaners to clients who contract us to analyze their data. These loaners are available for up to three (3) months for evaluation, when a client’s meter is being re-calibrated or repaired, or just when another meter is needed to get multiple plants “caught-up” on their data collection.

Special Discounts on New Meters:(<< drop down to the following)

VAI is the industry’s leading data analysis service provider. Since our ‘livelihood’ depends on the accuracy of our analysis we only use the industry’s BEST software and test equipment made by Emerson Process / CSI. Because of VAI’s endorsement of their product, we’ve been given the opportunity to offer exceptional discounts to our client’s who have us analyze their vibration data. If you’re looking for the absolute best price on CSI’s products and exceptionally accurate data analysis services, call us now for a quote.

Rentals:(<< drop down to the following)

Meter rentals may be the best option for companies who want to use and / or evaluate CSI’s vibration test equipment but not buy it. If that applies to you, call us now for an affordable quote. NOTE: If you contract VAI to analyze a minimum of 30 machines/month, you may qualify for a FREE loaner meter. Call us now at 815-742-1793 to discuss your needs.

FREE Database Creation, Maintenance and Optimization

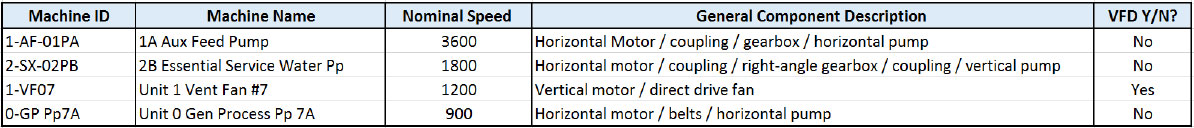

VAI specializes in creating Databases and Routes and our services are FREE to clients who select us analyze a minimum of 30 machines monthly for 12 months. All clients have to do is provide a list of the equipment they want in the program and in the format shown below (Excel format works best):

SAMPLE SPREADSHEET WITH MACHINERY INFORMATION

- Machine ID – Provide an machine “ID” (up to nine (9) characters) for each machine.

- Machine Name – Provide a name for each machine (up to 29 characters).

- Operating Speed(s) – Note: A/C motors typically operate at 900, 1200, 1800 and 3600 rpm. If not known, we may be able to obtain it from the vibration data. Also, state if on VFD

- General Component Description – This is what the machine looks like. Describe it as if you would describe it to someone over the phone (see examples above). Note if belts, coupling, or direct drive (DD).

Then provide one or more list of all machines listing them in the order you would like to collect the data (select an order which minimizes the number of steps taken in the plant). From your lists, VAI will create the database and route(s). Generally routes can contain as few as one (1) machine or as many as 70 however as a general guideline, routes should have between 20 – 30 machines to be efficient. If there are too many machines, time is wasted scrolling up and down to find the desired machines. If there are too few, time is wasted switching between routes.

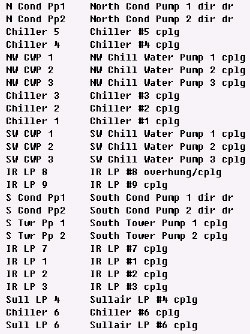

The following is an example of a “Route”:

Sample Route List

Initial Data Analysis and Periodic Trending:

Once the vibration database and route(s) have been created, and the initial data collected as part of the Data Collector Training we provide, we’ll help you download the data. It is important to note that while VAI can provide a good analysis and summary of machine health based on just the initial data, a minimum of five (5) dataset is needed to identify degrading issues, determine the ‘normal’ range vibration levels due to changes in operating conditions, and provide a more accurate analysis of the data in general. As such, clients should expect to collect the first five (5) datasets on an expedited schedule, say twice weekly for the first three (3) weeks. After the first five (5) sets of data have bee expedited, clients may take a more relaxed approach to the data collection. VAI strongly recommends monthly trending, however data can be collected once every two (2) or three (3) months. However, with less frequent trending, there may be a higher rate of unexpected failures. Monthly trending is recommended for all critical machines having rolling element bearings because they can progress from ‘good’ to ‘end of reliable life’ in as little as 45 days. Monthly testing will catch these types of failures whereas they may be missed with less frequent trending.

This is how we process client data:

1. The Category IV Analysts analyze the first five (5) datasets:

Our ISO Cat. IV Analysts analyze the first five (5) sets of data and work with clients to resolve any outstanding machine issues.

2. Two (2) ISO Cat. II Analysts

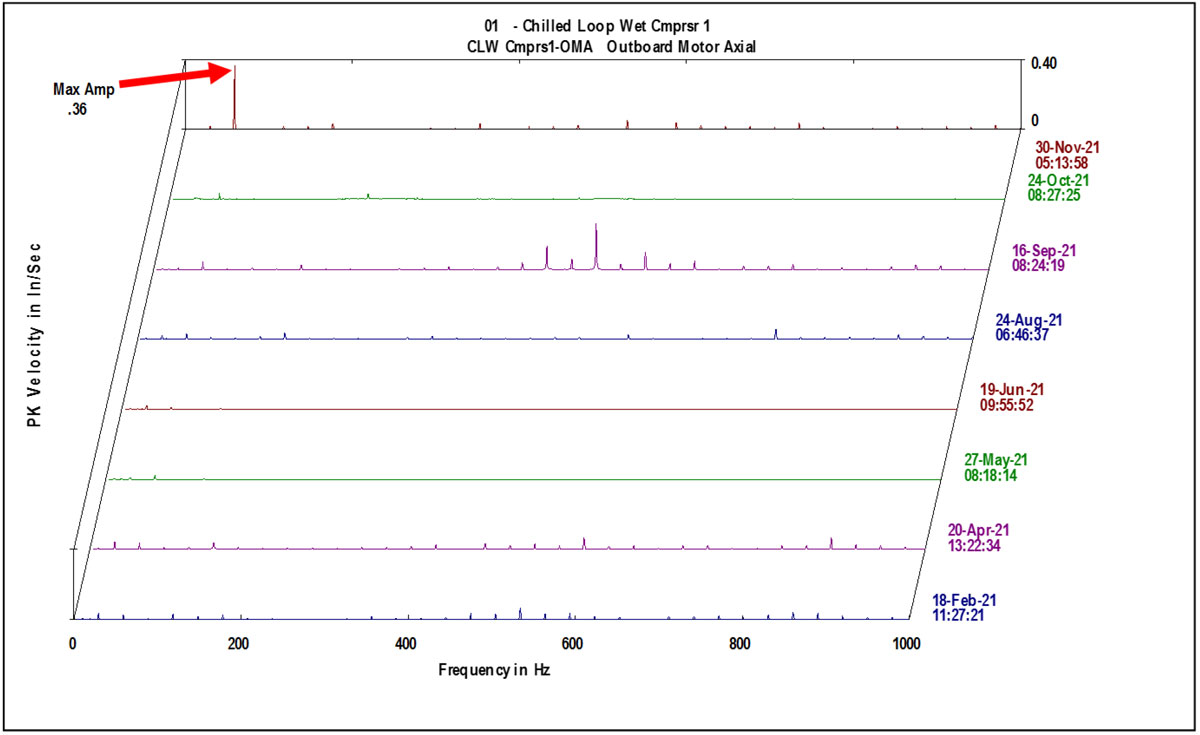

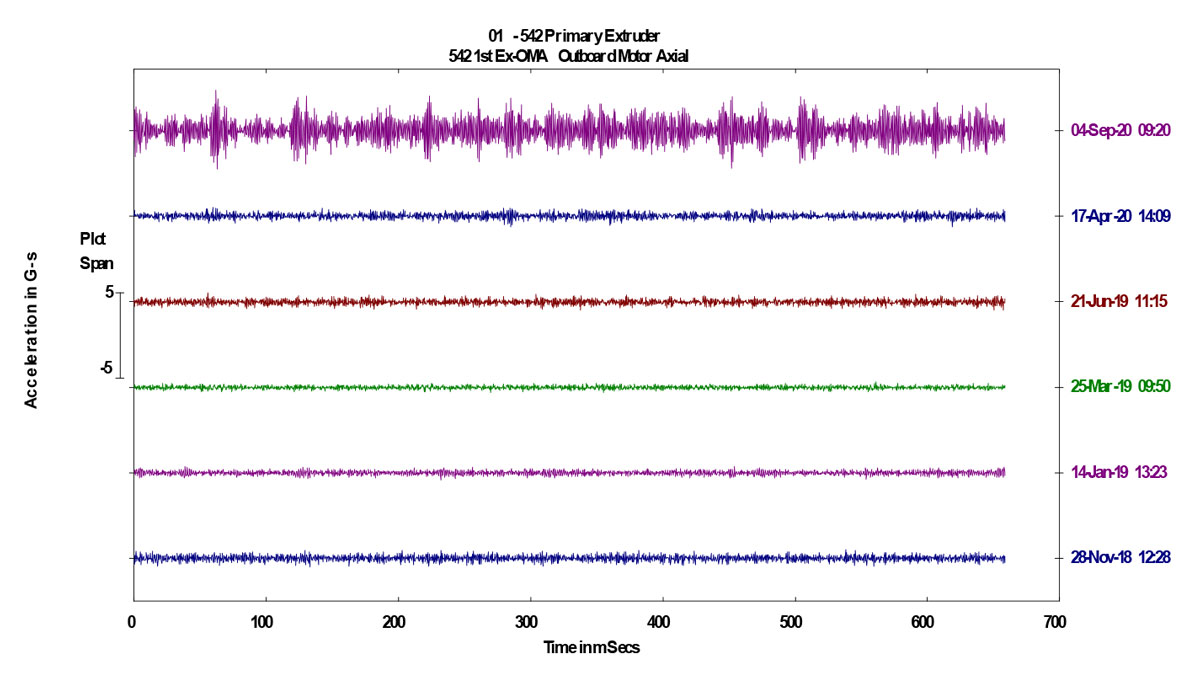

Beginning with the 6th dataset, up to two (2) Cat. II Analysts independently sort thru the data and identify any issues that point to a degrading issue (step changes, increasing trends and new frequencies). They then forward all issues to the ISO Cat. III’s for a more detailed analysis. The following is an example (refer to red arrow) of what the ISO Cat. II’s look for:

3. Two (2) ISO Cat. III Analysts

Next, up to two (2) ISO Cat. III Analysts INDEPENDENTLY analyze all issues. These Analysts are selected based on their backgrounds and experience so they can consider nearly all failure modes. They then provide recommended corrective actions and forward all issues to a ISO Cat. IV Analyst who then performs the highest review possible.

4. ISO Cat. IV Analyst

An ISO Cat. IV Analyst then performs the highest level of review possible. He also determines defect severity (GREEN / BLUE / YELLOW / RED), issues the report, and provides FREE 24/7 Technical Support. Our Cat. IV Analysts also provide on-going database maintenance and optimizations and keep the routes updated with changes. VAI has more ISO Certified Cat. IV Analysts than NASA and the US DOD and as a result, we can analyze data for specialized machines such as those listed in ‘Radiated Noise Reports’ and Nuclear Power Plants. We will also meet any database security requirements which means, NO data is stored on the cloud!

5. When additional datasets come in, we just repeat steps 2 – 4! Accurate reporting and recommendations! 24/7 Technical Support! No contractor expenses for collecting data! Clients receive FREE access to their database! And we’re very affordable!

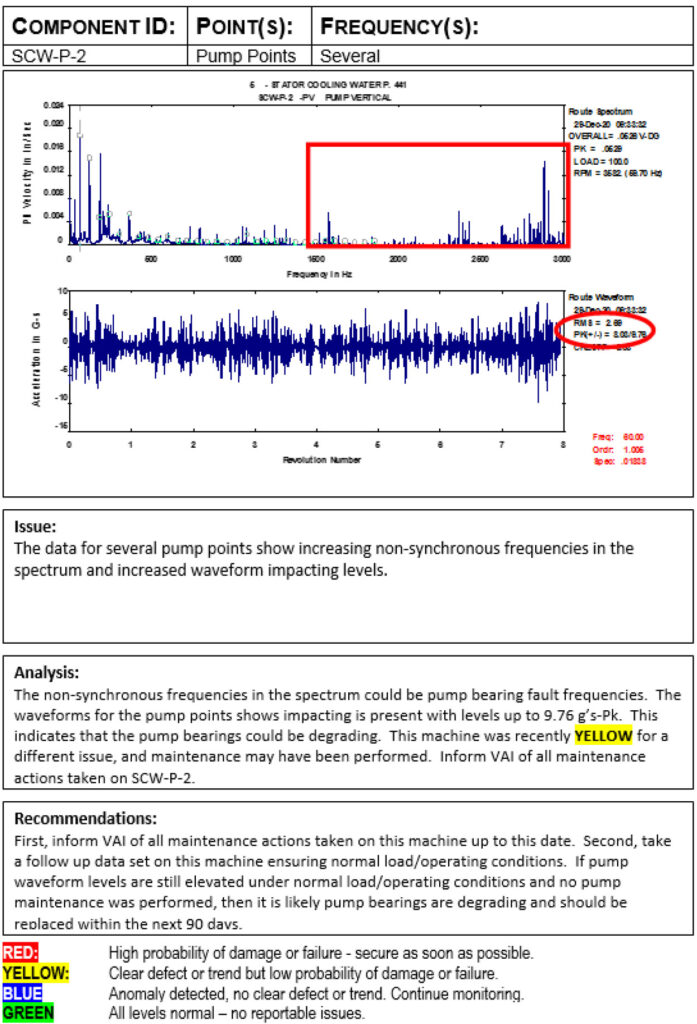

Our Reports:

Our reports are user-friendly and don’t contain any “fluff”. They are concise yet provide the information needed to understand all equipment issues.

Each component report has the following information (refer to screen print below):

- Component ID: The name or ID of the machine affected

- Point(s): The point or points affected

- Frequency(s): The frequency or frequencies affected

- Plot: Shows abnormal conditions flagged in RED

- Issue: Summarizes what the issue is

- Analysis: What VAI believes the issue is due to

- Recommendations: Summarize VAI’s recommended corrective actions.

- Component Health Colors:

- GREEN means all is well

- BLUE means an acceptable low level issue

- YELLOW means a low level defect has been identified

- RED generally means prompt corrective action should be taken

- Color Coded Sidebars: These ‘sidebars’ are located in the right margin, and provide a quick visual reference to the overall condition of each machine, allowing the reader to quickly find those machines that have significant issues.

KMK – please ask Ray Rhoe for a report with a RED sidebar in case I forget to provide it. The sidebar is missing from the following screen print

Regardless of your plant’s manufacturing processes, we provide accurate and affordable solutions. We can analyze vibration data for all types of machines, including motors, pumps, fans, chillers, extruders, compressors, gearboxes, unique one-offs and more.

COMPARE VIBRATION PROGRAMS

With VAI’s Services:

- You pay for only the machines we analyze

- VAI is not affected by employee illness, turnovers, vacations, strikes or transfers

- VAI provides FREE On-Site Data Collector Training; just collect and send us the data for analysis

- We ensure all test points are marked and in the best location possible

- We use the Industry’s best vibration test equipment and software

- VAI provides FREE access to the database software

- VAI’s provides exceptionally accurate analysis and corrective recommendations

- VAI provides FREE 24/7 Technical Support

- Your program can be up and running in as little as one (1) week.

Your Program’s Attributes

- Usually requires a full time employee

- Salary and benefits can cost up to $ 120,000 / year

- Employee turnovers will occur, with more resumes to read and interviews to conduct

- Who manages critical issues when your Analyst is on vacation, sick leave, quits or transfers

- Consider the expense for vibration database software (very expensive)

- New Analysts need time to attend training, learn the software and build the database

- Must consider training costs and “lessons learned” while coming up to speed.

- New Employee Training

- Technical Vibration Training

- Data Collector Training

- Database Software Training

- Realize that non-core duties may limit effectiveness of the Analyst

- Your Analyst can’t support the program 24/7

- New Analysts will have limited technical abilities