Vibration Analysis Reports

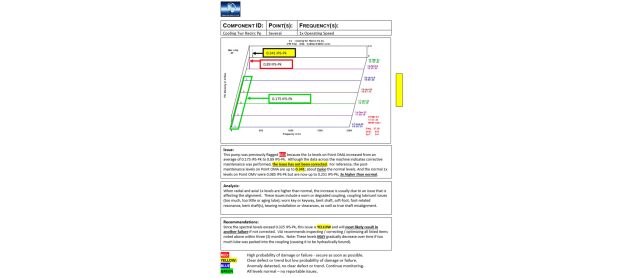

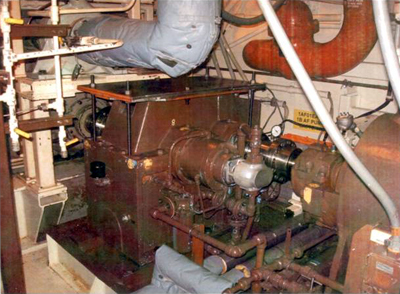

Using vibration analysis the experts at Vibration Analysts can detect faults in machinery long before catastrophic failure. Utilizing vibration analysis and coupling it with predictive maintenance, all types of machinery, from Ferris wheels to nuclear power plants, can be better maintained for lower costs. But what does a vibration analysis report actually look like? How…